PVDF membrane bioreactors provide a efficient solution for wastewater treatment. However, enhancing their performance is crucial for achieving high removal rates. This requires investigating various factors such as membrane properties, bioreactor structure, and operational parameters. Approaches to improve PVDF membrane bioreactor performance include modifying the membrane properties get more info through modification, optimizing hydraulic loading rate, and applying advanced control techniques. Through these strategies, PVDF membrane bioreactors can be efficiently enhanced to achieve high performance in wastewater treatment applications.

A Critical Review of Different Types of Hollow Fiber Membranes in MBR Systems

Membrane Bioreactors (MBRs) are increasingly employed for wastewater purification due to their high efficiency and reliability. Hollow fiber membranes play a crucial role in MBR systems, facilitating the separation of suspended solids from treated effluent. This study presents a comparative analysis of various hollow fiber membrane configurations, focusing on their performance characteristics and suitability in different MBR configurations. The membranes compared encompass cellulose acetate (CA), each exhibiting distinct structural properties that influence their contaminant rejection.

- , such as operating pressure, transmembrane pressure, and flow rate.

- The impact of different fouling mechanisms on membrane lifespan and operational stability will be explored.

- Furthermore, the study will emphasize potential advancements and future directions in hollow fiber membrane development for optimized MBR performance.

Membrane Fouling and Mitigation Strategies in PVDF-Based MBRs

Membrane fouling poses a significant challenge for the performance and longevity of polymeric membrane bioreactors (MBRs). Particularly, polyvinylidene fluoride (PVDF)-based MBRs can be susceptible to various fouling mechanisms, including deposition of extracellular polymeric substances (EPS), microbial colonization, and particulate matter accumulation.

These deposition events can drastically decrease the permeate flux, increase energy consumption, and ultimately negatively impact the effectiveness of the MBR system.

Several strategies have been proposed to mitigate membrane fouling in PVDF-based MBRs. These strategies can be broadly classified into preemptive and reactive approaches. Preventive measures aim to limit the formation of deposits on the membrane surface by optimizing operational parameters such as transmembrane pressure (TMP), hydraulic retention time (HRT), and feed water quality.

Corrective methods, on the other hand, focus on removing existing fouling layers from the membrane surface through physical or chemical treatment. Physical cleaning methods encompass backwashing, air scouring, and manual removal, while chemical cleaning employs agents such as acids, bases, or enzymes to dissolve or degrade fouling materials.

The choice of mitigation strategy depends on the specific fouling mechanisms present in the MBR system and the operational constraints.

Advanced Membrane Bioreactors for Industrial Wastewater Purification

Hollow fiber membrane bioreactor (MBR) technology has emerged as a cutting-edge solution for treating industrial wastewater due to its high removal efficiency and compact footprint. Recent advancements in hollow fiber design have resulted in enhanced performance, durability, and resistance to fouling. These improvements allow for the efficient removal of organic matter from a wide range of industrial effluents, including those from textile, food processing, and manufacturing sectors.

Industrial applications of hollow fiber MBR technology are becoming more prevalent. Its versatility enables its use in various treatment processes such as biological treatment, providing cost-effective solutions for industrial water reuse and discharge compliance.

- Moreover, ongoing research focuses on developing novel hollow fiber membranes with enhanced functionalities, such as the integration of antimicrobial agents or catalytic properties to address emerging contaminants and promote process intensification.

- As a result, hollow fiber MBR technology continues to be a key driver in the advancement of sustainable industrial wastewater treatment practices.

Modeling and Simulation of Flow Dynamics in PVDF MBR for Enhanced Separation Efficiency

This research analyzes the intricacies of flow dynamics within a polyvinylidene fluoride (PVDF) membrane bioreactor (MBR). Utilizing sophisticated computational fluid dynamics (CFD) simulations, we aim to optimize separation efficiency by precisely manipulating operational parameters such as transmembrane pressure, feed flow rate, and filter configuration. Through comprehensive analysis of fluid velocity patterns, shear stress distributions, and fouling formation, this study seeks to uncover key factors influencing separation performance in PVDF MBR systems. Our findings will deliver valuable knowledge for the design of more efficient and sustainable wastewater treatment technologies.

Integration of Membrane Bioreactors with Anaerobic Digestion: A Sustainable Approach

Membrane bioreactors with anaerobic digestion present a novel approach for treating wastewater. This alliance leverages the strengths of both processes, achieving greater removal rates of organic matter, nutrients, and pathogens. The produced effluent can then be securely discharged or even recuperated for land reclamation purposes. This sustainable solution not only reduces the environmental impact of wastewater treatment but also preserves valuable resources.

- Moreover, membrane bioreactors can function at reduced energy consumption compared to traditional processes.

- As a result, this integration offers a affordable and sustainable approach to wastewater management.

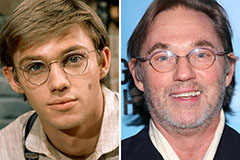

Mason Gamble Then & Now!

Mason Gamble Then & Now! Michael Jordan Then & Now!

Michael Jordan Then & Now! Danielle Fishel Then & Now!

Danielle Fishel Then & Now! Richard Thomas Then & Now!

Richard Thomas Then & Now! Jaclyn Smith Then & Now!

Jaclyn Smith Then & Now!